Capsule Minimal

The industrial revolution 5.0

552% of funding target

Highlights

Highlights

The Genius Capsule That Revolutionizes The Consumer Goods Market

Capsule Minimal has cracked the method for producing products without polluting the world! Why ship products containing 80% water in polluting plastic bottles from Turkey or anywhere else when there is tap water at home? The days of transporting billions of units of shampoo bottles or other water-based products are simply going to disappear. The company has developed groundbreaking technology that allows every household consumer to produce their own products, effectively replacing the factory and the entire polluting and unnecessary supply chain. A revolution – the same products we know, without plastic and without water. You insert a capsule into a reusable bottle, fill it with water, and the capsule prepares the product inside.

Europe is already there with strict regulations that will bring an end to the plastic era, while the Capsule Minimal technology provides them with a smart and simple solution that will adapt the products to the regulations. The company has ready-made capsules for products we all know, with a potential market value of $500 billion a year.

The company received grants of 4.3 million shekels from the Israel Innovation Authority IIA and is currently establishing a 250 square meter factory in Israel for the development and production of capsules.

Of Genius. Green. High quality.

The Development The World Has Been Waiting For.

95% Savings In Carbon Emissions!

The world longs for a solution that for the first time will put an end to the insane production process of products - which at the bottom line contain at least 80% water. Soap, shampoo, conditioner, cleaning products and many more products with a single-use plastic bottle are transported around the globe, in a particularly polluting journey of ships and trucks - and at the end of use are simply thrown into the trash, and that's after all of them contained a pinch of active substance and mainly - H2O, Yes… just water.

Illustrative Video

Revolutionary Technology. SUPER Revolutionary

Capsule Minimal managed to reach the unbelievable and develop a capsule with active ingredients, capable of simulating the factory production process - at your home.

The company's patent is based on the ability of the capsule to sustain the entire production process of the product inside the bottle, with high-quality and environmentally friendly components.

Patents And Strategic Investments

The company has intellectual property consisting of many patents and technological capabilities, which allow it to be protected, together with the ability to adapt to a variety of products and markets. The company is approved by the Innovation Authority and receives significant grants.

A Strong And Experienced Team

The company has a leading team with proven skills and knowledge in managing green technologies companies and ventures, including those that have been issued on the stock exchange and have been very successful. The knowledge and experience of the company's owners guide them on the way to developing another successful company, which will change the global production and development market.

The company was chosen to represent the State of Israel at the last international climate conference - COP28!

- The offer is not subject to the securities laws and corporate laws applicable to a company offering securities to the public. The Israel Securities Authority has not approved the publication of this offer document and has not reviewed it. Following the completion of the offer, the company will not be subject to disclosure requirements and corporate governance provisions designed to protect its investors and provide oversight by the Israel Securities Authority.

Pitch

Pitch

Game Over...

The world no longer tolerates environmental damage, and these words are not just empty promises.

Starting in 2025, many countries will begin marking and labeling products according to their carbon emissions.

In 2030, various types of packaging will already be prohibited from marketing by law - and in France, there is already a law that prepares the ground for the fact that in a few years, single-use plastic packaging will be prohibited.

This is no longer a recommendation - this is a global emergency with a real demand for change.

Already today, there is a growing demand in enormous dimensions for products that are environmentally friendly. According to representative surveys, 74% of the population of Western countries are interested in purchasing non-polluting products - but they have no idea how to do it!

A Breakthrough Product

The development of Capsule Minimal is a real Game Changer for a monstrous industry that no one knows how to stop. The capsule contains the ingredients contained in the original product, together with a kind of smart "map", which knows how to direct the entire production process, just like they do in a factory - only inside the consumer's home bottle.

In fact, you don't need to be a rocket scientist to make shampoo or any other water-based product. Placing the capsule in water from your tap will ignite the whole process and result in a finished product ready for use.

- Eco-friendly stainless-steel bottle with thousands of reuses

- Water from the home tap. Zero water transport. Up to 90% reduction in pollution

- A concentrated capsule of active ingredients. up to 20% of the volume

- Minimal, recyclable and eco-friendly paper packaging

- Based on natural active ingredients without harming the environment

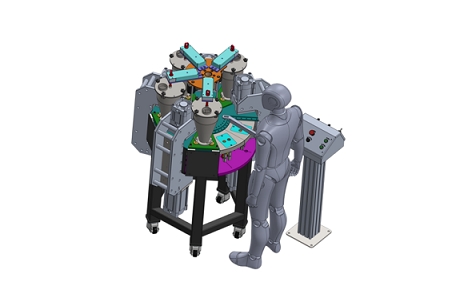

The Revolution Of Capsule Minimal - Innovative Capsule Production

The "programming" of the product is carried out using an ingenious and unique 3D printer that the company has developed, which actually determines how the final product will be created inside the bottle. The production of the capsule is done by printing powders in 3D into a product of compressed powders, which have a complex structure of layers containing micro capsules and basically all the "DNA" of how the product should form and look. In this context, the printer presents a high production capacity for a variety of products and physical structures, energy injection, low friction and other exclusive capabilities.

The printer development is expected to be finalized in the near future!

Which environmental Pollution Are We Going To Eliminate?

The production and distribution of water-based products consists of several stages all of which contribute to environmental pollution in insane amounts. Well, here's a reminder of the pollution chain, just before we work to eliminate it from the world!

- The products contain 20% chemical and synthetic components which are harmful to our health and harm the environment

- The packaging that bundles the products is a polluting factor in itself which is thrown away at the end of use

- A single-use plastic bottle, made of polymers derived from fossil fuels, which is transported by polluting trucks, ships and airplanes and finally thrown away at the end of use

- The products contain about 80% water that is transported all over the world - on land, in the air and at sea and produces heavy environmental pollution unnecessarily

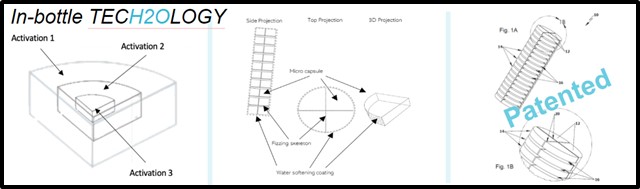

Amazing Technology Backed By Patents

In fact, the capsule is a solid compressed product, which contains all the components of the product - but also the DNA of how it is supposed to be built, assembled and manufactured. Yes, our shampoo has DNA :)

The company's patent enables the performance of a wide and complex range of operations, which until now were the property of the factories only. Among other things; Chemo-mechanical scaffolding skeleton, optimization of active substance ratios, density gradient and particle size, nano chemistry, material solubility control and more!

The company has intellectual property consisting of a series of patents. The first one has already finished the process in Israel (Granted) and the rest, three more in number, are in registration processes. The intellectual property combines (1) the concept of the capsule for the production of water-based products and its special chemical-physical structure. The technology knows how to do all the processes of the factory in exact timing and in order. and (2) The unique production process of 3D printing of powders is one of the advantages of the company, adaptability of production to a wide range of products and categories, which allows the company to become a significant player and take a share in any market in which it chooses to operate.

Take The Devil Out Of The Bottle...

An integral part of the development is the use of reusable and environmentally friendly bottles. These bottles are the result of the company's unique development. The bottle ultimately allows savings of up to 90% of the traditional logistic scope of that product. Beyond the production revolution, of preparing the products inside the bottle itself, it is a smart, practical and stylishly designed product. The bottle is made of quality stainless steel, can be used thousands of times and can even be recycled!

5 Principles - Golden Product

The company is guided by five guiding principles, which define the essence of the development and the company's perception of the market and the place that the unique solution is going to occupy;

1. Ecological product - reduction of over 95% of carbon emissions in the product supply chain, compared to traditional products.

2. Quality - the product is characterized by the quality of its ingredients, which are based on natural materials, as opposed to traditional products based on various chemical compounds.

3. Price - a convenient price that allows the customer to invest his money in the quality of the product - and not in unnecessary transportation and packaging.

4. Decoration - the company offers designed, modern and multi-purpose bottles, with an innovative and elegant concept, compared to the disposable plastic bottles.

5. Smart & Easy - the use of the product does not require special effort and enables a transition to ecological products practically and conveniently, with a pleasant use experience.

Team

Team

|

Certified public accountant with a master‘s degree in law (LLM) from Bar Ilan University in Israel and a BA degree in business administration from the Israel College of Administration.

As CEO and as a board member past and present in many corporations, he has extensive experience in managing large-scale companies in various fields, including energy, finance and cleantech. Ami has led many public and private offerings and various initiatives around the world.

In recent years, he has been active in the clean-tech industry as an inventor, entrepreneur and founder of a proven and active innovative production process, which significantly reduces carbon emissions in the polymer cycle and also took a significant part in the production of many environmentally friendly end products.

Ami is 51 years old, married, father of two daughters and lives in the center of the country.

|

|

Has a bachelor‘s degree in special education from Tel Aviv University in Israel.

Has extensive experience in production processes, human resources and procurement, strategic customer and supplier relations, supply chain, complex and special production projects and machine development. Hagar served as COO in a plastic recycling and manufacturing plant. Before that, she served as a purchasing manager, special adjustment for machines and special designation. In addition, Hagar has managerial experience and is responsible for dozens of employees in several different locations, has served as a manager of special projects and set up production sites.

Hagar is 47 years old, married, mother of three, lives in the north of the country.

|

|

Master‘s degree in veterinary and animal sciences, served as a chemist and research manager in leading institutions, has extensive experience in laboratory management, advanced scientific research, standardization and research procedures, chemical, biological and molecular laboratories and research. Extensive experience in managing advanced experiments in laboratories in research institutions. Nofer is 35 years old, married and mother of five and lives in the north of the country.

|

|

B.sc in Computer science, M.sc in bioinformatic, during PHD journey in bioinformatics.

Rare and invaluable experience in research and development in the field of data science tools. Vast experience and knowledge in bioinformatics methodologies.

Deep academic research in the fields of objects detection and RNA editing on parasites.

|

|

BA in Multi Business Administration

20+ years of experience in leading and growing global companies in the fields of infrastructure, tech, industry, communications, climate-tech, water, and energy.

Inspiring executive, proven track record of results.

Passionate about promoting new technologies and products that address the challenges and opportunities of the 21st century, driving the vision, strategy, and innovation as well as overseeing the sales and business development functions across different regions and sectors.

|